Innovation Campus, Houston, TX, USA

Further information and case study for this project can be found at the De Gruyter Birkhäuser Modern Construction Online database

The following architectural theory-based case study is not available at Modern Construction Online

Innovation Campus, Houston — Architectural Typology and Environmental Integration

This case study forms part of a wider design-research initiative that investigates the building envelope as a critical interface for architectural, structural, and environmental performance. Drawing on interdisciplinary frameworks and digital fabrication techniques, the Innovation Campus in Houston exemplifies how façade systems can function as agents of spatial identity, environmental responsiveness, and tectonic articulation. The project resonates with themes explored in Modern Construction Handbook (Watts, 2023), Modern Construction Envelopes (Watts, 2019), Modern Environmental Design (Watts, 2022), and both volumes of Modern Construction Case Studies (Watts, 2016; 2019), all of which underscore the envelope’s central role in performance-led architectural thinking.

Introduction

The Innovation Campus, designed by Newtecnic, exemplifies a seamless fusion of architectural ambition and technical precision, with the building envelope serving as the principal mediator between spatial intention and environmental performance. The project adopts an integrative methodology wherein digital workflows, interdisciplinary coordination, and fabrication intelligence converge to form a coherent architectural language. Consistent with Watts' position (2016, 2019, 2023), the design approach embeds envelope strategies within the very fabric of architectural and structural organisation, allowing construction detailing to serve as a primary contributor to both aesthetic identity and functional intelligence.

Precedent-Informed Design Strategy from Modern Environmental Design

Project 06 within the Innovation Campus directly adopts the loose-fit strategy articulated in Project 17 of Modern Environmental Design, embracing a design ethos that anticipates long-term adaptability and lifecycle efficiency. Cast-in sockets placed at regular intervals across slabs and vertical elements form an integrated servicing grid, which accommodates the flexible future deployment or reconfiguration of ventilation, lighting, and shading systems without the need for supplementary structural supports. This approach minimises material redundancy, simplifies system coordination, and facilitates independent upgrades with minimal disruption to core infrastructure. As a result, the building can evolve in step with changing technological or programmatic requirements, embodying a sustainable and flexible model for environmental design.

Typology and Campus Organisation

Architecturally, the Innovation Campus references the megastructural principles of post-war modernism, foregrounding modular expansion, infrastructural clarity, and spatial adaptability. The campus is organised into five functionally distinct but operationally integrated zones: laboratories, office suites, collaborative spaces, fabrication halls, and communal gathering areas. These zones are interlinked through continuous networks of circulation, environmental services, and façade articulation, enabling both spatial cohesion and operational flexibility.

This planning logic bears conceptual similarity to Kenzo Tange’s Yamanashi Press and Broadcasting Center (1966), where modular units and infrastructural spines articulated a framework for future growth and technological integration. Similarly, the Innovation Campus treats infrastructural systems not as concealed utilities but as spatial organisers and symbolic expressions, reaffirming the High Modernist conviction in architecture’s potential to articulate a rational, systematised order.

Influence of the IKM Museum, Istanbul on Façade Technology

The façade system of the Innovation Campus builds upon the technical and design precedents established by the IKM Museum in Istanbul—another Newtecnic project, previously documented in Modern Construction Case Studies (Watts, 2016). At both sites, parametric workflows are used to rationalise geometric complexity into manufacturable panel systems. High-precision processes such as CNC machining and laser cutting facilitate the production of metal panel façades with calibrated shading, while ventilated cavities enhance passive environmental performance. The IKM Museum’s innovative use of laser-cut metal cladding and CNC-profiled structural systems directly informs the folded rainscreen assemblies and modular aluminium components deployed in Houston.

Both projects exemplify the integration of structural logic and environmental modulation within an expressive architectural language. In Houston, façade fixings are designed not only for structural efficacy and thermal control but also for aesthetic clarity, enabling the envelope to communicate its tectonic and environmental roles in equal measure. This continuity in Newtecnic’s work demonstrates the evolution of a design language where digital tooling and environmental awareness are intrinsic rather than additive.

Circulation Systems and Infrastructural Logic

Circulation within the campus is facilitated by a series of walkways, ramps, and skybridges that double as service corridors and spatial connectors. These are constructed using dry-assembled steel trusses, designed with node-based detailing to allow ease of fabrication, speed of installation, and future disassembly. This modular construction strategy supports a lifecycle-aware approach, as outlined in Modern Construction Case Studies (Watts, 2016, 2019), where reversibility and reusability are essential parameters of sustainable design.

This infrastructural visibility evokes Claude Vasconi’s Palais des Congrès in Strasbourg (1975–76), where mechanical gantries and truss assemblies were celebrated as architectural elements rather than hidden systems. In a similar manner, the Innovation Campus elevates infrastructural clarity into a defining architectural gesture—pragmatic in function, yet poetic in form.

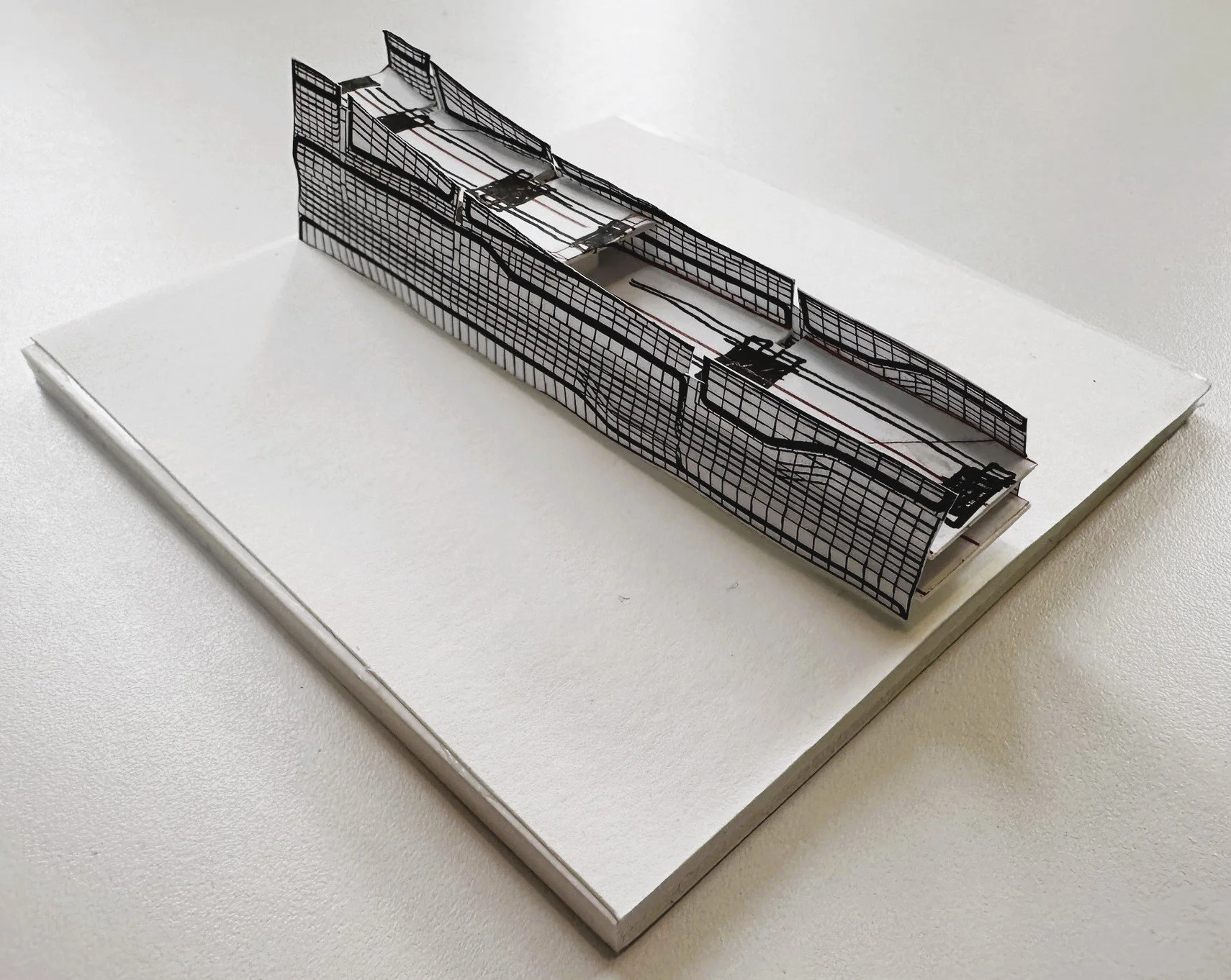

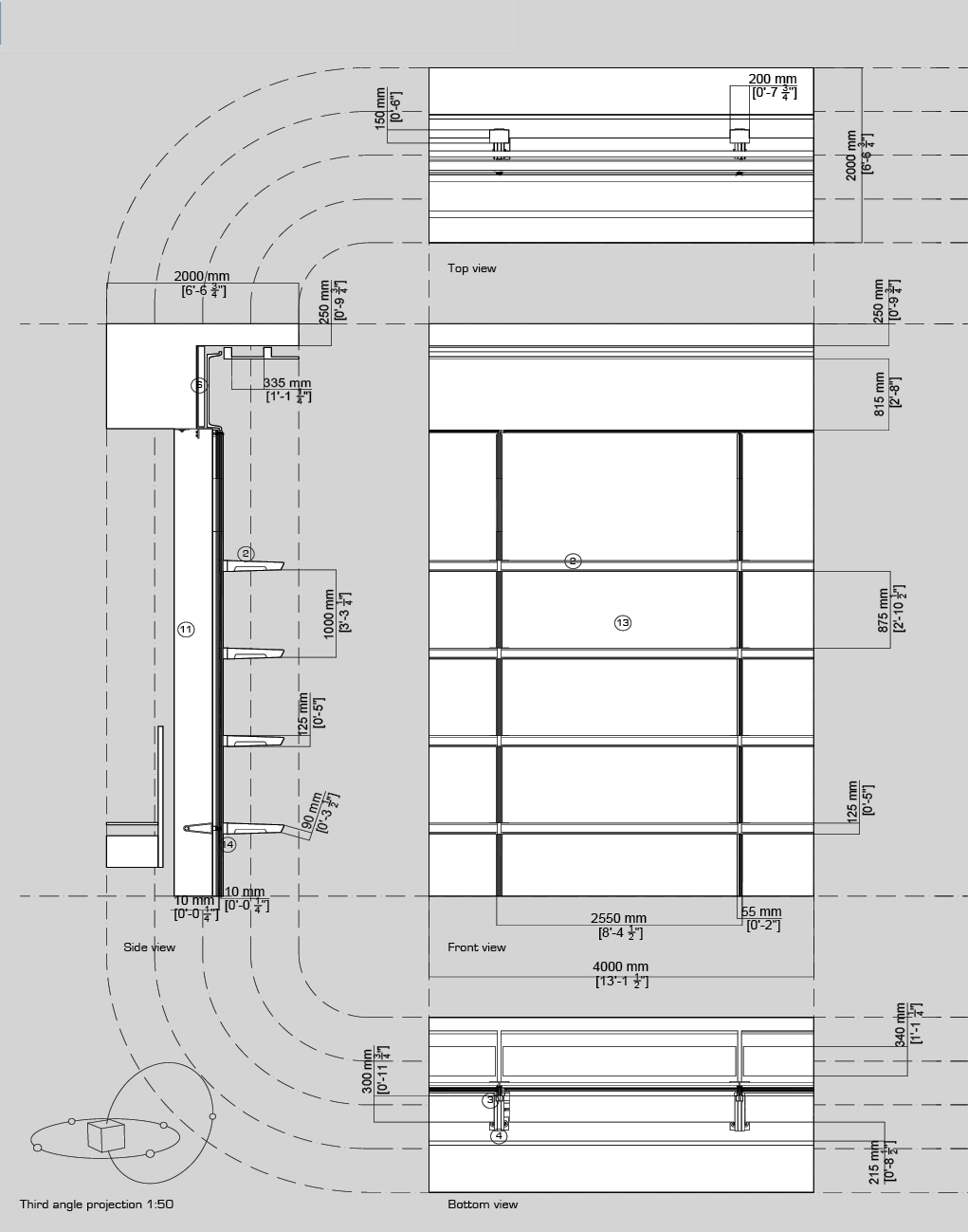

Facade Systems and Fixing Strategies

The envelope is composed of unitised curtain wall panels, pre-assembled off-site and installed via a rail system welded to the primary steel frame. Thermally broken aluminium frames provide a high-performance substrate for glazing, while CNC-profiled aluminium louvres are attached with concealed fixings calibrated for solar modulation. These are complemented by ventilated rainscreen panels fabricated from folded laser-cut metal sheets and supported on bracket-and-rail assemblies that maintain airflow and minimise thermal bridging.

Parametric detailing tools are employed to ensure alignment across all interfaces. Digital models coordinate all component geometries, and QR-coded parts provide traceability across manufacture, installation, and facilities management. This approach aligns with lifecycle-integrated construction strategies detailed in Modern Construction Handbook (Watts, 2023) and Modern Structural Design (Watts, 2022), ensuring that precision and maintainability are embedded from the outset.

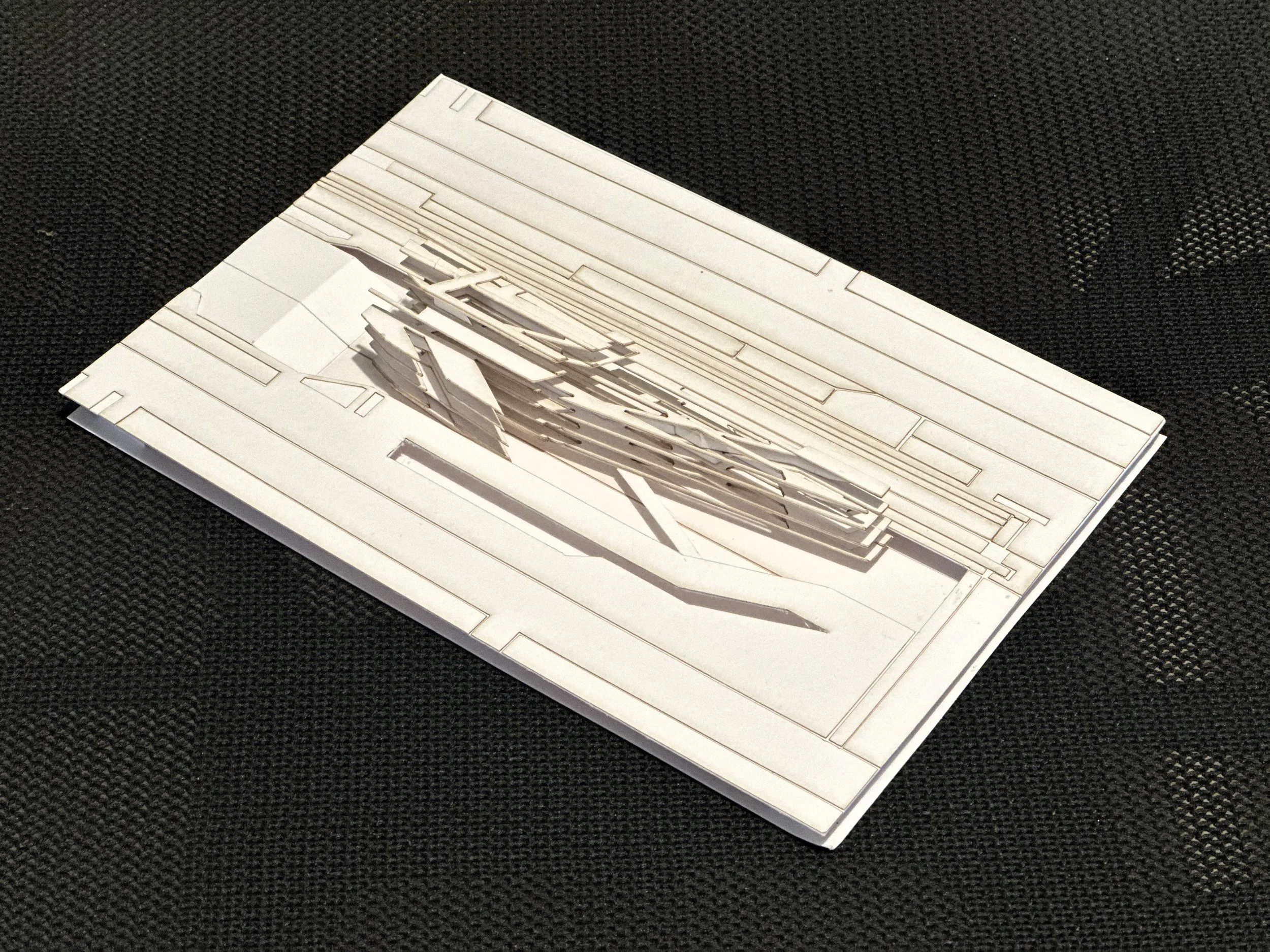

Parametric Fabrication and Modularity

Unlike conventional repetition-based façades, the Innovation Campus embraces mass customisation. Each panel variant is designed to respond to local conditions including solar trajectory, wind exposure, and interior programme. This is achieved through CNC-machined moulds for complex junctions, waterjet-cut steel components tagged for on-site sequencing, and a digital twin framework that embeds performance data, construction tolerances, and lifecycle tracking within each component.

The file-to-factory pipeline underpins the entire fabrication and assembly process, reducing on-site errors and ensuring that design intelligence is retained throughout. This strategy mirrors the principles described in Modern Construction Envelopes (Watts, 2019), where parametric modelling informs both geometry and fabrication logic.

Climatic Responsiveness and Environmental Systems

The building massing is divided into articulated volumes separated by vertical thermal corridors that serve as both service voids and environmental buffers. These spaces enable natural ventilation and reduce thermal bridging across the envelope. On south-facing elevations, a double-skin façade promotes stack-driven airflow, while rooftop photovoltaic arrays—mounted on adjustable steel frames—facilitate seasonally adaptive energy harvesting.

These strategies reflect the passive design principles advocated in Modern Environmental Design (Watts, 2022), where façades are conceptualised not as static enclosures but as dynamic mediators of environmental interaction.

Tectonic Expression and Detail Clarity

The architectural language of the Innovation Campus is defined by its tectonic transparency. Structural frames, shading systems, and façade elements are left visible, and their assembly processes are deliberately expressed. Rather than concealing fasteners and seams, the design highlights them, turning construction detail into architectural narrative.

This expressive strategy recalls Le Corbusier’s Unité d’Habitation (1947–52), where systematised structure and solar modulation were integral to spatial and climatic performance. In a similar vein, the Innovation Campus employs algorithmically defined shading geometries and rhythmically modulated panels to produce variation within structural order.

The design approach embodies the critical regionalism of Frampton (1995) and the performative rationalism of Behne (1926), integrating expressive tectonics with environmental function. It is consistent with Watts’ methodology (2016, 2019), wherein detail, performance, and architectural expression are inextricably linked.

Conclusion

The Innovation Campus in Houston reinterprets the megastructural tradition through the lens of digital fabrication, environmental responsiveness, and tectonic expression. Designed by Newtecnic, it stands as a paradigm of contemporary architectural practice in which spatial composition, construction intelligence, and environmental adaptation are synthesised into a unified whole. Drawing on the theoretical and technical frameworks advanced in Modern Construction Handbook (Watts, 2023), Modern Construction Envelopes (Watts, 2019), Modern Environmental Design (Watts, 2022), and Modern Construction Case Studies (Watts, 2016, 2019), the project demonstrates that the building envelope can serve not only as a performative skin but as the generative matrix of architectural identity.

References

Addington, M. and Schodek, D. (2005) Smart Materials and Technologies in Architecture. Oxford: Architectural Press.

Banham, R. (1976) Megastructure: Urban Futures of the Recent Past. London: Thames & Hudson.

Behne, A. (1926) Modern Functional Building. Santa Monica: Getty Research Institute (trans. 1996).

Frampton, K. (1995) Studies in Tectonic Culture: The Poetics of Construction in Nineteenth and Twentieth Century Architecture. Cambridge, MA: MIT Press.

Kolarevic, B. (2003) Architecture in the Digital Age: Design and Manufacturing. New York: Taylor & Francis.

Le Corbusier (1952) Œuvre Complète 1946–1952, Vol. 5. Zurich: Girsberger.

Lin, Z. (1995) Kenzo Tange and the Metabolist Movement: Urban Utopias of Modern Japan. London: Routledge.

Picon, A. (2010) Digital Culture in Architecture: An Introduction for the Design Professions. Basel: Birkhäuser.

Watts, A. (2016) Modern Construction Case Studies. 1st ed. Basel: Birkhäuser.

Watts, A. (2019) Modern Construction Case Studies. 2nd ed. Basel: Birkhäuser.

Watts, A. (2019) Modern Construction Envelopes. 3rd ed. Basel: Birkhäuser.

Watts, A. (2022) Modern Environmental Design. Basel: Birkhäuser.

Watts, A. (2022) Modern Structural Design. Basel: Birkhäuser.

Watts, A. (2023) Modern Construction Handbook. 6th ed. Basel: Birkhäuser.